- Zhengzhou, Henan, China

- Contact : market@slicermachinery.com

- Phone/Whatsapp : +86 150 3944 1352

Choosing the right cheese slicer depends on factors like cheese type, slice thickness options, capacity, and material durability. In this guide, we’ll walk through key considerations for selecting a cheese slicer that meets both home and commercial needs. We also introduce Dosing Machinery’s versatile slicers, designed for processing various foods—from cheese to meats, vegetables, fruits, and bread. With our focus on quality, customer service, and competitive pricing, Dosing Machinery offers reliable solutions to elevate your food slicing experience. Discover the perfect slicer to meet your needs and optimize your food preparation!

Examples: Brie, Camembert, Cream Cheese

Soft cheeses have a creamy, spreadable consistency that can be delicate and easily damaged. Slicing these cheeses requires a gentle approach, often with a thin, wire-style slicer to avoid squashing and to retain the cheese’s shape.

Examples: Mozzarella, Havarti, Monterey Jack

These cheeses have a firmer texture than soft cheeses but still require careful handling. A blade slicer that cuts with precision but doesn’t compress the cheese is ideal to maintain its softness and prevent stickiness.

Examples: Cheddar, Gouda, Provolone

With a firmer texture and more defined shape, semi-hard cheeses are easier to slice consistently. Adjustable thickness options on a slicer are helpful for these cheeses, allowing for a range of slice sizes suited to different uses, from sandwiches to cheese boards.

Examples: Parmesan, Asiago, Pecorino

Hard cheeses are dense and require a strong, sturdy blade to cut through without crumbling. A heavy-duty slicer with robust construction is essential for achieving clean slices in these firm cheeses.

Examples: Aged Cheddar, Gruyère, Manchego

Aged cheeses develop firmer textures over time, often needing sharper blades to achieve even slices. These cheeses can benefit from adjustable slicers that can handle their hard exteriors without crumbling the more delicate interior.

Hard cheeses are dense and require a strong, sturdy blade to cut through without crumbling. A heavy-duty slicer with robust construction is essential for achieving clean slices in these firm cheeses.

Cheese slicer is essential tools for achieving consistent, even slices that enhance the presentation, texture, and flavor of cheese. Whether used in a restaurant, deli, or home kitchen, a quality cheese slicer ensures that each slice is uniform, enhancing the visual appeal and experience of eating cheese. The way cheese is sliced can also influence how it melts, pairs with other foods, and holds its shape, making the slicer an invaluable tool for any cheese lover or food business.

Different types of cheese require specific slicing approaches due to their unique textures and densities. Here’s a classification of the main cheese types and the ideal slicing methods for each:

Different cheeses call for specific slicing approaches due to their varying textures and firmness. Softer cheeses like Brie or Mozzarella need gentle slicing to avoid damage or crushing, which is why a slicer with a thinner or wire-based blade is often preferred. Harder cheeses like Parmesan or Pecorino require a robust, sturdy blade capable of handling their density without crumbling.

Dosing Machinery’s Recommendation: Dosing Machinery offers slicers equipped with robust blades ideal for handling a wide range of cheese types. Whether you need a gentle slicer for soft cheeses or a high-power slicer for hard and aged cheeses, our models are crafted to provide precision, ease, and adaptability for various textures.

Having control over slice thickness is essential, especially when preparing cheese for different purposes, such as thin slices for sandwiches or thicker cuts for cheese boards. Adjustable thickness settings allow you to customize slices, ensuring the cheese is cut to match any dish’s requirements.

Dosing Machinery’s Recommendation: Many of Dosing Machinery’s slicers come with adjustable thickness options, giving you flexibility and control over slice size. These settings are particularly useful in commercial kitchens or catering settings where varied slice sizes are often needed to accommodate different presentation styles and culinary needs.

For businesses slicing cheese in bulk, such as commercial kitchens, delis, or catering services, a high-output slicer is essential to keep up with demand efficiently. A cheese slicer with a strong motor and high-capacity output can save time and labor, allowing for quick, continuous slicing without compromising on quality.

Dosing Machinery’s Recommendation: Dosing Machinery’s high-capacity slicers are built for heavy-duty performance, making them ideal for bulk slicing. Our models ensure high slicing speeds while maintaining consistency and precision, perfect for businesses looking to streamline their cheese slicing processes without sacrificing quality.

Choosing a slicer made from high-quality materials, especially stainless steel, is critical for hygiene, durability, and easy maintenance. Stainless steel is resistant to rust and corrosion, easy to clean, and maintains a sanitary cutting surface over time.

Dosing Machinery’s Commitment: Dosing Machinery uses premium-grade stainless steel in its slicers to ensure durability, safety, and longevity. Our slicers are designed with food safety in mind, meeting hygiene standards and delivering long-lasting performance even in high-demand settings.

Handheld Cheese Slicers

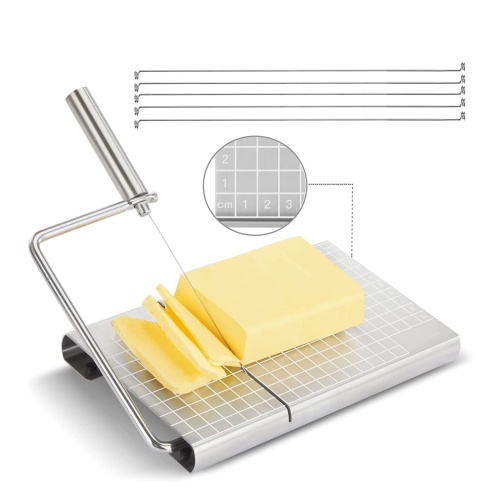

Handheld slicers are simple, easy-to-use tools that are ideal for light, casual use in home kitchens. They typically consist of a wire or small blade attached to a handle, allowing the user to slice soft to semi-hard cheeses with minimal effort. While convenient for occasional use, handheld slicers are less efficient for slicing large quantities and may not provide the consistency needed for professional presentations.

Machine Cheese Slicers

Machine cheese slicers are designed for larger-scale, high-efficiency slicing, making them ideal for commercial settings like delis, restaurants, or catering businesses. With their powerful motors, adjustable thickness settings, and durable blades, these slicers handle a wide range of cheese types with speed and precision. Machine slicers also allow for greater control over slice thickness, making them suitable for consistent, high-volume slicing that handheld models cannot match.

Dosing Machinery’s Recommendation: For commercial or bulk slicing needs, Dosing Machinery’s high-capacity cheese slicers offer reliable, precise slicing with customizable thickness options. Our machine slicers are equipped with robust construction to handle even the toughest cheeses, making them perfect for professional environments where consistency and efficiency are priorities.

Multi-Functional Slicers

Multi-functional slicers are versatile machines that can handle various foods beyond just cheese, such as meats, vegetables, fruits, and bread. This versatility is ideal for commercial kitchens and delis that require a single tool capable of performing multiple tasks. Multi-functional slicers save both time and space, as they eliminate the need for separate equipment for each type of food, making food prep more efficient.

Dosing Machinery offers a comprehensive range of high-quality food slicers designed to meet the diverse needs of food businesses, from small delis to large commercial kitchens. Our slicers are built with advanced technology and durable materials to ensure precision, reliability, and ease of use across various applications.

Dosing Machinery slicers are built for flexibility, allowing operators to slice not only cheese but also meat, vegetables, fruits, and bread. This versatility makes our slicers an ideal choice for kitchens that require efficient, multi-functional equipment capable of handling a variety of slicing needs.

Designed to maximize efficiency, Dosing Machinery slicers deliver high slicing speeds without sacrificing quality or precision. Our models cater to the fast-paced environment of commercial kitchens, helping to streamline food preparation and boost productivity.

Dosing Machinery slicers are engineered for quick and smooth slicing, reducing wait times and allowing businesses to serve more customers efficiently. Our powerful motors and sharp, durable blades enable our machines to cut through cheese and other foods with ease, maintaining high performance even during peak hours.

Our slicers come with customizable thickness settings, allowing operators to achieve the perfect slice for each application. Whether you need ultra-thin slices for sandwiches or thicker cuts for charcuterie boards, Dosing Machinery slicers offer precise control to meet any specification.

We design our slicers with user-friendly components that are easy to disassemble, clean, and reassemble, ensuring a hygienic slicing environment and minimizing downtime. Stainless steel construction also makes our machines resistant to rust and corrosion, preserving quality and safety over time.

Quality and Innovation

At Dosing Machinery, we prioritize innovation and quality to deliver slicers that meet the evolving needs of modern food processing. Our slicers are crafted using state-of-the-art technology and durable, food-safe materials to ensure consistent performance and longevity. By continuously researching and integrating new technologies, we stay at the forefront of the industry, providing customers with reliable, high-efficiency slicers suitable for a variety of applications.

Each Dosing Machinery slicer is designed with precision and care, ensuring it not only meets but exceeds industry standards. Our commitment to quality means that every slicer is built to provide smooth, accurate slicing, minimizing food waste and maximizing presentation quality.

Customer Service and Support

Dosing Machinery is dedicated to providing exceptional customer service, with a team ready to assist customers at every step—from the initial inquiry through to setup, operation, and maintenance. Whether you need advice on selecting the right slicer model, guidance on setup, or troubleshooting tips, our knowledgeable support staff is always available to help.

We also provide comprehensive user guides and maintenance resources to ensure that our customers get the most out of their slicers. Our commitment to customer satisfaction means that you’ll receive responsive and personalized support tailored to your business needs, helping you keep your operations running smoothly.

Competitive Pricing

Dosing Machinery offers competitive pricing, ensuring you receive premium quality at a fair and accessible price. We believe that affordability should not mean compromising on quality, which is why our slicers are designed to offer both value and durability. Our pricing structure reflects our commitment to providing cost-effective solutions for businesses of all sizes, from small delis to large commercial kitchens.

By choosing Dosing Machinery, you gain access to high-performance, multi-functional slicers that deliver excellent return on investment. With our products, you benefit from both the reliability and cost-efficiency necessary for sustainable business growth.

Fill out the form below, and we will be in touch shortly.