- Zhengzhou, Henan, China

- Contact : market@slicermachinery.com

- Phone/Whatsapp : +86 150 3944 1352

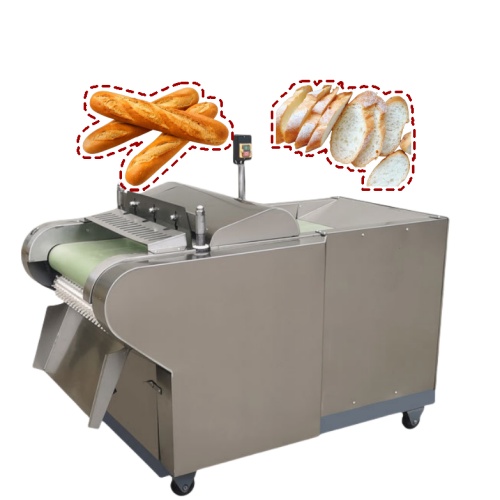

In the food industry, especially within bakeries and food processing plants, efficient and reliable bread slicer machine is crucial to maintaining both quality and productivity. Consistently sliced bread not only improves the aesthetic appeal of the product but also ensures uniform portion sizes, which are essential for customer satisfaction and cost control. Manual slicing can lead to inconsistencies, slow production times, and increased labor costs, all of which can affect a business’s bottom line. That’s why investing in an advanced, automated bread slicer machine, like our baguette slicer, is key to optimizing operations. It enhances speed, reduces waste, and guarantees precision, ultimately supporting businesses in delivering high-quality products while meeting the growing demand.

A commercial baguette bread slicer machine can slice large volumes of bread in a fraction of the time it would take to do so manually. This increase in speed directly translates into higher production output, allowing bakeries and food processing facilities to meet demand without compromising quality.

With automated slicing, businesses can minimize downtime, resulting in smoother, continuous operations. A high-performance slicer keeps pace with high-demand production, improving overall workflow.

One of the biggest challenges in manual slicing is inconsistency. Each slice of bread needs to be uniform in size and thickness to ensure a professional, high-quality product. An industrial baguette slicer guarantees uniform slices every time, improving product presentation and customer satisfaction.

With adjustable specifications, the bread slicer machine allows businesses to tailor the slice thickness according to their needs, whether it’s for standard baguette slices or customized portions for sandwiches, toasts, or other recipes.

Automated slicing eliminates the need for manual labor, reducing the reliance on human workers and associated costs. The bread slicer machine operates independently, which means fewer staff members are required for slicing tasks, freeing up workers for other essential duties.

It also reduces the chances of injury or strain from repetitive slicing motions, contributing to a safer work environment.

Manual slicing can lead to uneven cuts, which can create waste in the form of unusable bread pieces. A high-quality baguette bread slicer machine minimizes this waste by ensuring every slice is even and accurate, thus maximizing the yield from each loaf of bread.

Additionally, with an efficient and precise slicer, you can optimize the use of ingredients and reduce losses during production.

In the fast-paced environment of commercial bread production, the ability to slice baguettes quickly and consistently can make a significant difference in both the quality and efficiency of operations. Here are the key advantages of using a high-quality baguette slicer:

Bread slicing may seem like a straightforward task, but bakeries and food processing facilities often face several challenges that can impact efficiency, product quality, and costs. A high-quality baguette bread slicer machine, like the one we offer, is designed to address and overcome these challenges. Here are some common issues faced in bread slicing and how our baguette bread slicer machine provides effective solutions:

Challenge: One of the biggest problems with manual slicing is the inconsistency in slice thickness. Even small variations can affect the final product’s quality, appearance, and uniformity, which is crucial for commercial-scale production.

Solution: The baguette bread slicer machine guarantees precise, uniform slices with adjustable thickness settings. Whether you need thin slices for sandwiches or thicker ones for toasts, the bread slicer machine can consistently produce the exact size required, eliminating the risk of inconsistent cuts and ensuring a professional finish every time.

Challenge: Manually slicing baguettes, especially in large quantities, can be time-consuming. This slow pace can lead to production bottlenecks, delays, and increased labor costs, which ultimately impact the bottom line.

Solution: Our baguette bread slicer machine offers rapid slicing capabilities, increasing production speed while maintaining high quality. The bread slicer machine can process large volumes of bread in a short amount of time, helping bakeries and food processors meet growing demand without compromising on efficiency.

Challenge: Manual bread slicing is a physically demanding task that requires a skilled workforce. This reliance on manual labor can increase costs and create challenges in terms of training, turnover, and workplace injuries due to repetitive motions.

Solution: The baguette bread slicer machine automates the slicing process, reducing the need for human intervention. This not only decreases labor costs but also frees up staff for other critical tasks within the bakery or food processing plant. The automated system allows for quick, simple operation and reduces the risk of injury or fatigue associated with manual slicing.

Challenge: Baguettes and other bread types are delicate, and improper handling during slicing can cause them to crumble or lose their shape. This damage leads to product waste and inconsistent results.

Solution: The baguette bread slicer machine is designed to handle bread gently, ensuring that each loaf is sliced cleanly and precisely without causing damage. The solid bracket and high-quality steel blades ensure a stable, firm grip on the bread, allowing the bread slicer machine to cut through without crushing or distorting the loaf. This results in clean, intact slices that maintain the quality and texture of the bread.

Challenge: Manual slicing often results in uneven slices, leaving behind waste or unusable ends. This waste not only reduces the overall yield from each loaf but also leads to higher costs and inefficiencies.

Solution: With its precision cutting mechanism, the baguette bread slicer machine ensures that each slice is of the same size, minimizing waste. The adjustable settings allow for perfect slices every time, maximizing the yield from each loaf and reducing excess waste that would otherwise need to be discarded.

Challenge: As demand increases, bakeries often struggle to keep up with high production volumes using manual methods. This can result in slower production times, longer lead times, and missed opportunities to meet customer orders.

Solution: The baguette bread slicer machine is built to handle high volumes, making it an ideal solution for businesses experiencing growth or peak demand periods. Its powerful motor and efficient slicing mechanism allow it to process a large number of loaves quickly, ensuring that even the busiest operations can keep up with demand without sacrificing quality.

Challenge: Many bread slicing solutions are limited in terms of customization, which can be problematic when different slice specifications are needed for various recipes or customer preferences.

Solution: The baguette slicer offers adjustable specifications, allowing users to customize the slice thickness based on the type of bread or specific requirements. Whether it’s for standard baguette slices or for more unique bread types, the slicer adapts to different needs, ensuring flexibility in production.

Challenge: Bread slicing machines that require frequent maintenance or are prone to breakdowns can cause unexpected downtime, disrupting operations and delaying production schedules.

Solution: Our baguette slicer is designed for durability and minimal maintenance. Equipped with high-quality materials such as 201 stainless steel and a national standard copper core motor, the slicer is built to last and handle heavy use without constant repairs. This reduces downtime and ensures that the slicer remains in optimal working condition, contributing to smoother operations.

Dosing Machinery’s baguette slicer is packed with features that ensure reliability, efficiency, and quality, making it the ideal solution for commercial bread production. Here’s a closer look at the key features that set our slicer apart:

The bread slicer machine is built with thickened 201 stainless steel, a durable material known for its corrosion resistance and long-lasting performance. This high-quality steel construction ensures that the bread slicer machine can withstand the rigors of daily use in a commercial kitchen or bakery.

The stainless steel design also makes the bread slicer machine incredibly easy to clean, preventing the buildup of crumbs, flour, and other residues that can accumulate during bread slicing. Regular cleaning is crucial for maintaining food safety standards, and the smooth, non-porous surface of stainless steel allows for quick and effective sanitation.

Our bread slicer machine features a widened conveyor belt designed to handle larger quantities of bread at once. This feature enhances productivity by allowing the machine to hold more loaves at a time, reducing the number of cycles required to process a high volume of bread.

The wider conveyor belt not only boosts efficiency but also minimizes the risk of jams or bread displacement during slicing. By accommodating more bread at once, it ensures a smoother, uninterrupted slicing process, which is essential for fast-paced environments.

One of the standout features of our baguette bread slicer machine is its adjustable specifications, giving users the flexibility to customize slice thickness according to their needs. Whether you require thin slices for sandwiches, medium slices for toasts, or thicker portions for other applications, the bread slicer machine can be easily adjusted to meet your specific requirements.

This level of customization makes the bread slicer machine suitable for a wide variety of bread types and baking processes, from artisanal baguettes to mass-produced loaves, ensuring that the machine can adapt to your production demands.

Solid Bracket and Waterproof Switch

The bread slicer machine is equipped with a solid bracket that ensures the machine remains stable and secure during operation. This sturdy construction is crucial for maintaining consistent performance, especially during high-speed slicing.

Additionally, the waterproof switch adds an extra layer of safety and convenience. In a commercial kitchen or bakery setting, where moisture can be present, having a waterproof switch reduces the risk of electrical issues and ensures safe operation. It also contributes to the slicer’s durability, allowing it to continue functioning optimally in a variety of working conditions.

Our baguette bread slicer machine is powered by a national standard copper core motor, known for its excellent efficiency and reliability. Copper motors are renowned for their superior conductivity, which translates into consistent power delivery and smooth operation, even during heavy use.

The high-performance motor ensures that the bread slicer machine can handle high volumes of bread slicing without overheating or slowing down. It also contributes to the overall longevity of the machine, reducing the need for frequent repairs or replacements, making it a long-term investment for your business.

In a competitive market filled with various bread slicing machines, it’s crucial to choose a bread slicer machine that not only meets the demands of your business but also offers superior performance, durability, and ease of use. Our baguette bread slicer machine stands out from the competition due to its unique combination of features, high-quality construction, and Dosing Machinery’s commitment to excellence. Here’s how our bread slicer machine compares to other options on the market:

Our bread slicer machine: Built with thickened 201 stainless steel, our baguette bread slicer machine ensures unmatched durability and corrosion resistance. The high-quality stainless steel not only withstands the rigors of daily use but also makes cleaning a breeze, keeping your slicer in top condition with minimal effort.

Other Slicers: Many slicers in the market use lower-grade materials, which may rust or corrode over time, particularly in humid or high-moisture environments. These materials can compromise the slicer’s longevity and food safety, leading to frequent repairs and replacements.

Our bread slicer machine: The widened conveyor belt on our slicer allows for the processing of larger volumes of bread at once, improving efficiency and reducing operational time. This feature is especially useful for high-demand bakeries and commercial food processors, ensuring smoother workflows during peak production hours.

Other Slicers: Many competitor slicers come with narrower conveyor belts, limiting the amount of bread that can be processed at once. This results in longer slicing cycles and slower production speeds, making it harder to meet high-volume demands.

Our bread slicer machine: Our slicer offers adjustable specifications for slice thickness, providing flexibility and customization for various types of bread and customer preferences. Whether you need thin slices for sandwiches or thicker cuts for specialty breads, the slicer adapts to your needs.

Other Slicers: While some slicers on the market offer preset slice thickness options, many lack the flexibility to adjust beyond a limited range. This can be problematic if your bakery or processing plant needs to slice different bread types with varying thicknesses or specifications.

Our bread slicer machine: We prioritize safety and durability with a solid bracket that ensures the machine stays stable during operation, and a waterproof switch for added protection against electrical hazards in commercial kitchen environments. These features contribute to the slicer’s long-lasting performance, even in busy, moisture-rich environments.

Other bread slicer machine: Some competitors may lack the robust bracket and waterproof features, leading to potential instability or safety concerns in high-pressure environments. This can lead to costly repairs and a shorter lifespan of the machine.

ur Slicer: Equipped with a national standard copper core motor, our slicer offers consistent power, efficiency, and reliability. Copper motors are known for their superior conductivity, which ensures smooth operation even under heavy loads, providing long-term value and minimizing the risk of overheating.

Other Slicers: Many slicers use motors made from less efficient materials that can overheat or fail under high-demand conditions. These motors often result in downtime, reducing productivity and increasing operational costs due to frequent repairs or replacements.

Our Slicer: Our slicer is equipped with two high-quality steel knives, designed to provide clean, precise cuts with minimal effort. Steel maintains its sharpness over time, ensuring consistent quality in every slice without the need for constant blade replacements.

Other Slicers: Some slicers use low-grade or single blades that may wear out faster or fail to provide the same level of cutting precision. Over time, these knives can lead to uneven slices, damaging the bread and leading to inconsistent product quality.

Fill out the form below, and we will be in touch shortly.